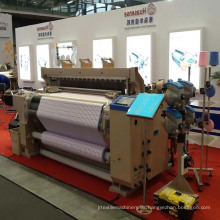

Picanol Omni / Toyota / Tsudakoma Air Jet

Información básica

Modelo: Han9100

Descripción del producto

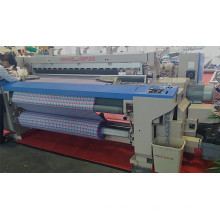

Working range | Cotton and non-cotton yarn |

Reed width (cm) | Nominal:150,170,190 ,210,230 260,280 330 360 Useful reeding width:reduct 0-60cm |

Filling selection | 1 color 2 color at will |

Weft density range | 6-300pick/cm |

Motor | 3.5kw,4.6kw selected according to the certain model |

Shedding | Plain type 2-8pcs heald frame |

Positive cam machine,4-10pcs heald frame | |

Dobby(mechanical),upper negative dobby or electronic dobby,2-16 heald frame (according to customer’s demands) | |

Let-off | Electronic let off-ELO |

Mechanical let-off | |

Flange diameter:800mm | |

Take-up | Mechanical take-up |

Electronic take-up | |

Upper and down temple(according to the varity of fabric) | |

Waste filling removel | Mechanical take-up 3 roller |

Cutter | Mechanical cutter |

OPERATION | – DRIVEN BY RUSH START MOTOR.STOP BY ELECTROMAGNETIC BRAKE AT PRGRAMMED POSITION |

ARRANGE,RUN,FORWARD INCHING,REVERSE INCHING,PROGRAMMED POSITION STOP AFTER | |

ONE CYCLE REVERSE ROTATION. | |

BEATING | CRANK BEATING,SWORD BEATING SYSTEM OIL BATH LUBRICATION SYSTEM. |

FILLING INSERTION : | SINGLE PUMP (PLUNGER TYPE SPRING PRESSURE SYSTEM) DOUBLE NOZZLE (NEEDLE TYPE CERAMIC ) STBILIZER SYSTEM FEELER – IR FEELER OR OPF FEELER,USING OPTICAL CABLE. |

YARN PACKAGE STAND | FLOOR MOUNTED HORIZONTAL STAND FOR – 4 PACKAGE.(2 COLOUR ) |

CATCH CORD | SPINDLE TWISTING SYSTEM. |

TEMPLE | TOP MOUNTED,2 BARREL TYPE WITH 2 RING |

WATER SUCTION | SLIT TUBE SUCTION (BLOWER TYPE ) |

Working range | Polyster yarn |

Reed width (cm) | Nominal:150,170,190 ,210,230 260,280 330 360 Useful reeding width:reduct 0-60cm |

Filling selection | 1 color 2 color at will |

Weft density range | 6-60pick/cm |

Motor | 3.5kw,4.6kw selected according to the certain model |

Shedding | Plain type 2-8pcs heald frame |

Positive cam machine,4-10pcs heald frame | |

Dobby(mechanical),upper negative dobby or electronic dobby,2-16 heald frame (according to customer’s demands) | |

Let-off | Electronic let off-ELO |

Mechanical let-off | |

Flange diameter:800mm | |

Take-up | Mechanical take-up |

Electronic take-up | |

Upper and down temple(according to the varity of fabric) | |

Waste filling removel | Mechanical take-up 3 roller |

Cutter | Mechanical cutter |

OPERATION | – DRIVEN BY RUSH START MOTOR.STOP BY ELECTROMAGNETIC BRAKE AT PRGRAMMED POSITION |

ARRANGE,RUN,FORWARD INCHING,REVERSE INCHING,PROGRAMMED POSITION STOP AFTER | |

ONE CYCLE REVERSE ROTATION. | |

BEATING | CRANK BEATING,SWORD BEATING SYSTEM OIL BATH LUBRICATION SYSTEM. |

FILLING INSERTION : | SINGLE PUMP (PLUNGER TYPE SPRING PRESSURE SYSTEM) DOUBLE NOZZLE (NEEDLE TYPE CERAMIC ) STBILIZER SYSTEM FEELER – IR FEELER OR OPF FEELER,USING OPTICAL CABLE. |

YARN PACKAGE STAND | FLOOR MOUNTED HORIZONTAL STAND FOR – 4 PACKAGE.(2 COLOUR ) |

CATCH CORD | SPINDLE TWISTING SYSTEM. |

TEMPLE | TOP MOUNTED,2 BARREL TYPE WITH 2 RING |

WATER SUCTION | SLIT TUBE SUCTION (BLOWER TYPE ) |

TALLER:

TALLER:

CONTACTO:

CONTACTO: QQ: 601642991

QQ: 601642991 Grupos de Producto : maquinaria de tejer > Telar de chorro de aire

Premium Related Products